Variable Pumping

Smarter Pumping Strategies That Cut Energy Costs

Roth Southeast’s Variable Pumping solutions reduce energy costs and extend equipment life by delivering chilled water flow based precisely on demand. Unlike constant-speed systems that run at full capacity regardless of need, our smart pumping strategy adjusts flow rates dynamically, improving efficiency without compromising comfort.

Savings At a Glance

Typically these pumps run 24/7, so reducing the horsepower by just one horsepower is an annual savings of $525. Multiply that across multiple pumps or higher horsepower units, and the savings quickly scale into the thousands – all while extending equipment life and reducing peak energy demand.

What Is Variable Pumping?

Variable pumping, also known as variable flow pumping, uses variable frequency drives (VFDs) to adjust pump speed in response to system demand. The result is optimized energy usage, lower operating costs, and better control over building cooling performance.

By implementing this strategy, we help clients reduce over-pumping, eliminate unnecessary pressure, and gain deeper visibility into their system’s performance.

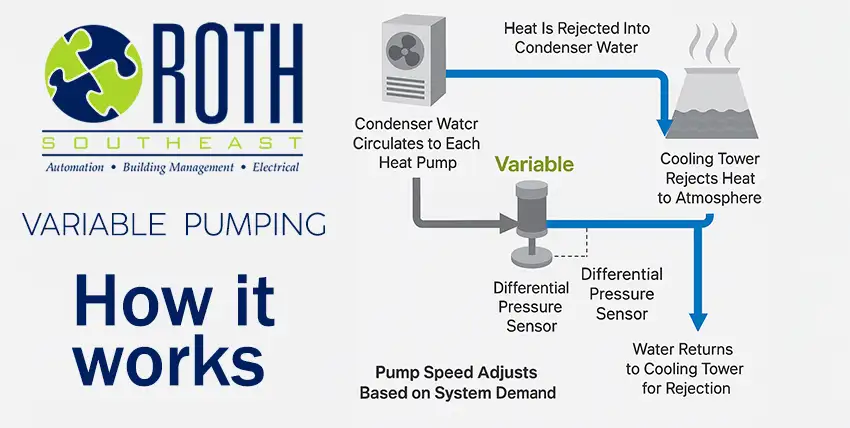

How It Works

Heat Is Rejected Into Condenser Water

In a condenser water heat pump system, the heat in the building is rejected into the condenser water that is pumped to each heat pump.

Condenser Water Circulates to Each Heat Pump

The heat is then carried in the water to the cooling tower where the heat is rejected to the atmosphere through the cooling tower.

Water Temperature Rises Through Heat Transfer

In a typical design, from 5 years ago or older, the pumps that moved this water

through the system were constant volume. Constant volume means that water is

pumped through every unit, even if it is not running.

Water Returns to Cooling Tower for Rejection

A unit will have approximately 3 gallons of water per minute per ton of air conditioning pumped through it.

Cooling Tower Rejects Heat to Atmosphere

New technology, with variable frequency drives and controls, allow us to more efficiently control this water flow. Pumping water consumes horse power (i.e. electricity). New variable speed pumping systems reduce the water pumped though the system by using a control valve that stops the water from flowing through a unit that is not operating.

Tower Cooled Water Returns to Pumps

A typical unit that is sized properly would only need to run 2/3rds of the time. In addition to this, condo/ apartment/ hotel buildings tend to have people that are away or at work for long periods of time where the systems will have even less run time.

Pumps Circulate Water Back to Heat Pumps

Another common issue at these types of buildings is that the system is actually over pumping or pumping more than is required. This new type of control allows you to also get energy savings by controlling this condition as well.

Heat Is Rejected Into Condenser Water

In a condenser water heat pump system, the heat in the building is rejected into the condenser water that is pumped to each heat pump.

Traditional Systems Use Constant Flow Pumps

The variable pumping system uses the existing pumps, but slows them down so they pump less water.

Variable Systems Use Differential Pressure Sensors

By pumping less water, the motor consumes less horsepower.

Pump Speed Adjusts Based on System Demand

Typically these pumps run 24/7, so reducing the horsepower by just one horsepower is an annual savings of $525. In addition, the slower these pumps run, the less wear there is on the pump seals and bearings.

Expert Installation, Ongoing Support, and 24/7 System Monitoring

Professional system installation, maintenance, and monitoring are accomplished through Roth Southeast skilled service network. Customers are assured prompt response time, replacement parts within 24 hours and reliable service. In addition to turn-key installations, Roth Southeast offers customers an equipment maintenance option as well as 24 hour monitoring on all installations

Benefits Of Variable Pumping

-

Lower Energy Bills

Reduces pumping energy by matching output to demand. -

Improved System Balance

Eliminates over-pumping and system strain. -

Enhanced Comfort Control

Delivers consistent temperatures where needed.

-

Extended Equipment Life

Minimizes wear on pumps and connected systems. -

Real-Time Adjustments

Responds dynamically to building load changes. -

Proven ROI

Fast payback with long-term utility savings.

Next Steps

See what smarter pumping can save you. Our team can evaluate your pumping system and estimate potential energy savings using variable flow strategies.